Multi-series, full-specification, top industrial level 3D printing software and hardware facilities, covering SLM, SLS, SLA, FDM, PolyJet and other mainstream technologies, supported by a professional technical team, providing one-stop services such as design, proofing, post-processing, etc..

Service Cases

Topology optimization of aircraft bearing structure

for the original design through additive manufacturing technology to reduce the weight of the structure, while meet the stiffness and stress requirements.

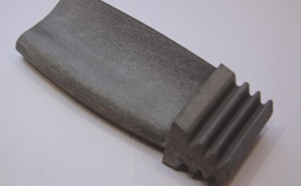

Engine blades

The core components of engine are prone to damage during use, additive manufacturing technology can be used to repair engine blades. Re-manufacturing of laser cladding can reduce the cost of blade use.

Rapid prototype of automobile air conditioner

Through 3D production system, the automobile manufacturers can conduct a relatively high-precision assembly and testing after rapid prototyping of automobile air conditioner, so as to help enterprises greatly reduce error costs and effectively improve market competitiveness.。

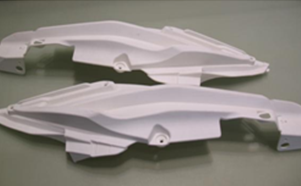

Motorcycle front cover

Motorcycle manufacturers use 3D printing technology to make motorcycle front cover, which enforces flexibility and creativity in the development stage, saves lots of time and money costs, comprehensively improves their core competitiveness in industrial design.。

Conformal Lattice Tire

Conformal Lattice Tire generated according to the geometric shape is developed and designed by the Additive Design and Manufacturing Laboratory of McGill University in Canada. Based on the geometric shape of the ordinary tire, an optimized mesh with a hollow center is automatically generated through a topology optimization algorithm The structure, on the premise of ensuring the strength of the tire, achieves the purpose of weight reduction; and makes the air flow through the tire, with excellent heat dissipation performance.

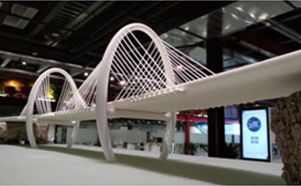

Ruyu Bridge model

The model of "Ruyu Bridge" is designed by the International Joint Research Center of Bridge Art aesthetics of Chongqing Jiaotong University, and printed by Gonggangzhihui with SLS technology

Students works of Sichuan Fine Arts Institute

The students of Sichuan Academy of Fine Arts designed and modeled, and with the help of 3D printing technology, they perfectly copied the 3D printing innovation base of "3D Zhihui", a subsidiary of Gonggangzhihui.

Works by Shen Yunqing of Sichuan Sculpture Art Academy

Samples of sculpture works by Shen Yunqing of Sichuan Sculpture Art Academy, the cobwebs and spiders were printed by Gonggangzhihui with SLS technology and SLA technology respectively.

Operation planning model of rock chordoma

According to the surgical planning model of petroclinal chordoma, CT diagnosis of chordoma in the site of craniocervical slope is made. The lesions are located in the middle cranial fossa and posterior cranial fossa, with deep location and adjacent to the brain stem and other important structures. Therefore, it is difficult to operate clinically. Preoperative 3D printing of color model helps to develop surgical strategies, and endoscopic surgery through nasal cavity reduces surgical risks, thus achieving accurate treatment and saving surgical costs.

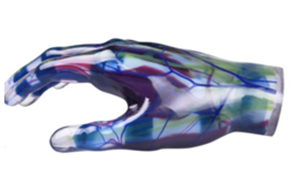

Medical education model of normal hand anatomy

Normal hand anatomy medical education model, based on CT image data, 3D full-color printing 1:1 model, clearly display the anatomical position relationship of the bone and muscle of the hand, as well as the specific trend of blood vessels and nerves, suitable for medical education and accurate medical service.

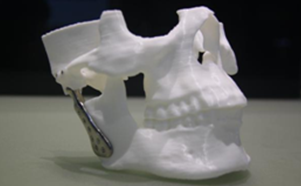

Temporomandibular joint replacement

The Left temporomandibular joint was lost due to bone tumor resection on the left side of the mandible. The maxillofacial model was reconstructed according to the CT data of the patient, and the affected joint was reconstructed according to the undamaged joint, so as to determine the position and shape of the articular fossa and condyle. The mandible was designed with a porous design, with the purpose of reducing the implant weight and facilitating tissue growth to ensure the implant stability.

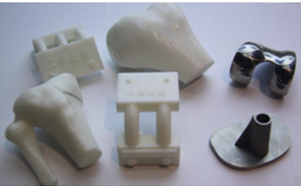

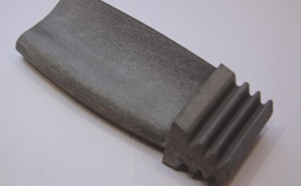

Total knee replacement

Total knee replacement is required for osteoarthritis and other diseases in the knee. According to the reconstructed model, the lower limb force line was fiend, the lower limb osteotomy amount and angle were determined, and the osteotomy guide plate and the prosthesis model were designed.